The electronics industry emerged in the 20th century, and Now it is one of the largest global industries. Here you can find a large variety of appliances and devices such as radios, computers, televisions, stereos, semiconductors, transistors, integrated circuits, etc.

Many electronic devices and their components are manufactured using CNC machining, since electronic sector needs this type of technology that offers cost-effective mass-production, high precision, durability, and excellent processing accuracy. Some electronic components or devices are critical to errors and they demand ultra-high precision. All these demanding attributes can be achieved using CNC technology.

CNC machines can process a diversified range of materials whether conductive, non-conductive metals, or plastics. Another advantage of using CNC machining is that it can create the tiniest semiconductors with very high precision. Any small or large part with any level of geometrical complexity can be manufactured as well.

The superb reliability offered by CNC processing makes it a prior choice for electronics manufacturers, where it is used to create small and large assembly productions and prototyping of several components. Sometimes it is required tight tolerances to be used to manufacture a part. CNC machining also offers products with high tolerances.

Another merit of using CNC machining is that it is capable of mass-production in a short timeframe because there is no tooling stage before production. Using other technologies like 3D printing or die casting does not serve the purpose as efficiently as CNC technology does. If we want any design modifications, then it only requires amending the CAD design to make slight changes or altering the whole design.

In this article, we will elaborate how CNC machining is commonly utilized in the electronics industry. What are the benefits of using this technology? Some important components will also be discussed manufactured using it.

Benefits of Using CNC Machining in the Electronics Industry

There are numerous benefits that the electronics industry is availing from CNC machining. A few of them are discussed below

Ultra-High Precision Part Manufacturing

Electronics parts require a high degree of precision. Otherwise, inaccuracies in the production can be highly critical. This is the major factor that makes CNC technology a better choice over other manufacturing technologies. As all the process is automated with little human involvement. That brings precision into the process.

Faster Mass-Production

In CNC machining, creating a part requires only a few steps. First CAD design is created then it is converted into numerical instructions in the form of CAM code. The next machine is set up and finally, the machinist will be ready to execute the machining action. Once all these steps are accomplished then creating any number of parts is just a matter of necessary time to be spent in operating the machine. In this way, we can easily manufacture a mass-production at faster rates.

Cost-Effective Part Manufacturing

One of the main advantages of CNC machined electronics parts is that it offers prototyping and mass-production at very reasonable prices. If it is required to manufacture a prototype to test a new design, then it can be done easily at lower prices. Other than this, this technology reduces the cost of labor and chances of errors that cost schedule delays and material to scrap.

Excellent Processing Accuracy and Efficiency

As the whole machining process is controlled through computer instructed numerical instructions and with a little minimum human assistance. This automation capability is the reason behind the excellent processing accuracy and efficiency offered by CNC machining. Which is extremely paramount in the electronics industry.

Electronics Parts Manufacturing Using CNC Machining

CNC technology is extensively used by the electronics sector due to many obvious reasons discussed above. Parts that are being created by electronics manufacturers, few important of these are discussed below

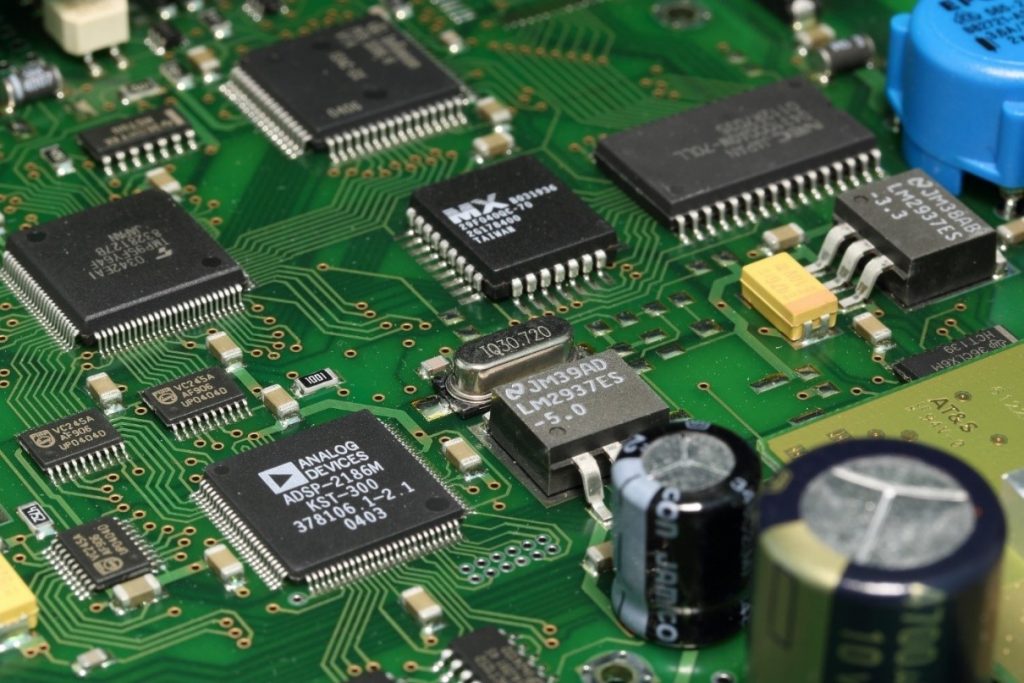

Semiconductors

The creation of semiconductors brings a revolution to the electronics industry. It is considered that the MOSFET (metal-oxide-semiconductor field-effect transistor) or MOS transistor is the most extensively manufactured device in human history. The semiconductor materials like silicon and aluminum nitride find immense use in semiconductor creation. They are machined using precision CNC technology.

These tiny semiconductor devices require to have tight tolerances and durability which is easily achieved by CNC machining. The semiconductor components made using the CNC process include solder pad stencils, flex circuit stiffeners, wafer chucks, etc.

Printed Circuit Boards (PCBs)

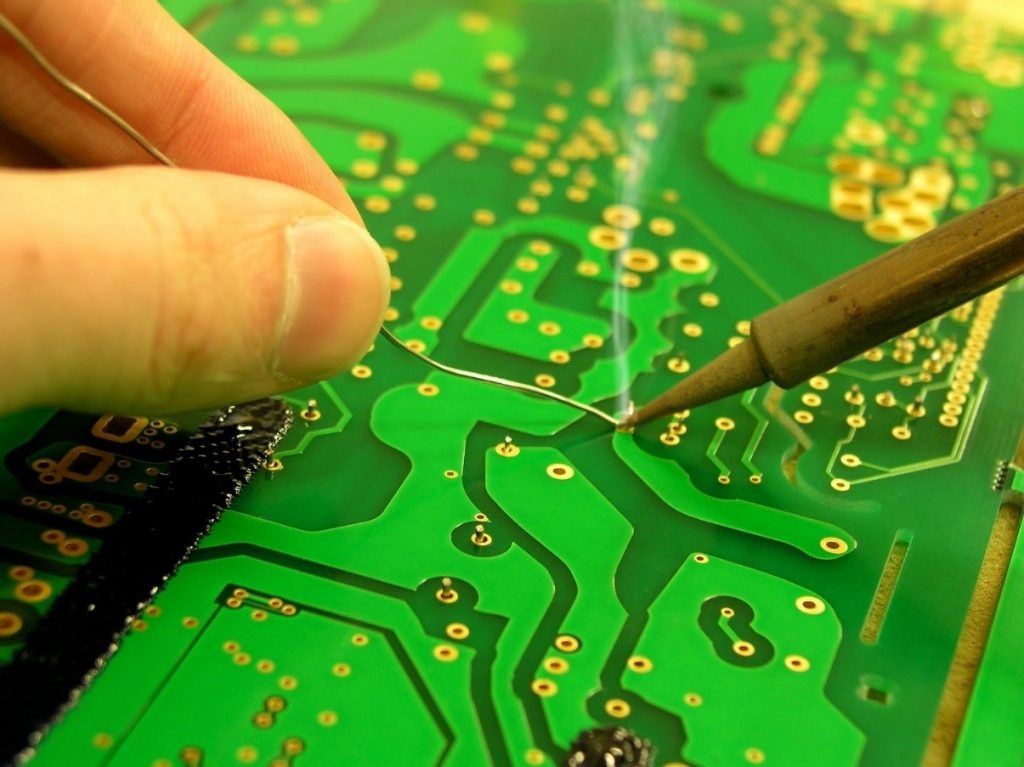

PCBs are printed circuit boards that mechanically brace and electrically connect different electronic components. It uses many conductive tracks, pads, and other features. These are etched onto a non-conductive substrate. Etching plays an important in PCB creation.

Most PCBs are manufactured by an etching process that involves hazardous chemicals. That may not be suitable for many entities like offices, homes, etc. to use and can be extremely venerable to devastating incidents.

But manufacturing printed circuit boards using CNC machining does not involve working with hazardous chemicals. That makes the CNC process a more feasible and safer choice. It can easily carve out functional PCBs that will be safer to use at vulnerable entities.

There are numerous benefits of CNC machined PCBs such as eradicating hazardous chemicals, being cheaper, manufactured in less time, and being durable.

Heat Sinks

Heat sinks are passive heat exchangers used to prevent electronics devices from overheating. These are installed in numerous devices for heat dissipation so that a device can operate properly. It absorbs the heat generated in electronics parts and carries it out.

CNC machined heat sinks are highly precise and effective in their heat dissipation mechanism. Atypical fin patterns created provide an upper edge against overheating. Frequently used materials for heat sinks include stainless steel, aluminum or copper alloys, etc.

Precision machined heat sinks have several advantages like fabrication with fin patterns, numerous materials choices, faster mass-production, etc.

Connectors and Sockets

CNC machining can also be used to make different connectors and sockets used for different purposes. For example, joining two electronic devices like an electronic musical instrument to be attached with an amplifier to amply the sound. So to connect these two devices, we require connectors and sockets made of metal to establish an electrical connection between them.

Since these connectors and sockets require tight tolerances and high precision to serve the purpose of connecting two devices effectively. The tiniest error will lead to disintegration while establishing a connection. Therefore, CNC machining is a preferred choice. The materials normally used in the manufacturing of such devices are copper alloys. This heading includes electronics devices like contacts, sleeves, pins, etc.

The advantages of precision CNC machined connectors and sockets are tight tolerances, high precision, durability, material variety, etc.

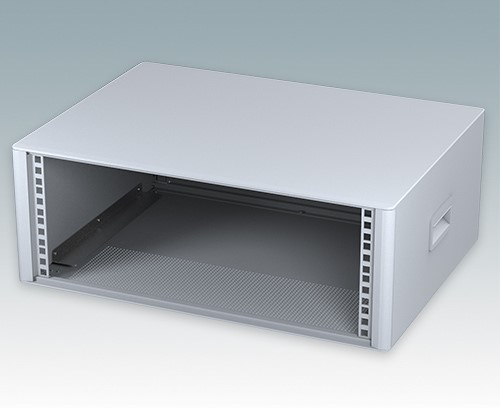

Electronics Casings and Enclosures

While CNC technology is capable of creating semiconductors and printed circuit boards, on the other hand, it can also be used to manufacture casings and enclosures for different electronics devices which act as exterior shells or casings.

Making these electronics casings and enclosures with precision CNC technology has many advantages over using other technologies such as die casting, 3D printing, etc. Because they have ultimate precision and good surface finishes. Many electronic devices such as computers, cameras, CROs (Cathode Ray Oscilloscopes) need sturdy exterior shells. So that the internal hardware remains safe.

Advantages of CNC machined castings and enclosures are sturdiness, a variety of materials to choose from, excellent surface finishes, durability, etc.

Conclusion

Electronics devices are used in almost every electronic device. Inaccuracies in any device can be extremely crucial and may result in disastrous outcomes. Therefore, mostly electronics devices are manufactured using CNC machining technology. That makes sure the production of ultra-high precision parts.

There are numerous other manufacturing technologies but there are not preferred against precision CNC machining. Because CNC machined electronics parts have ultimate accuracies and durability. Which is important in the electronics industry.

If you are looking for a trusted CNC machining workshop then you are at the right place. We are one of state-of-the-art CNC machining workshop in China. If you require any custom-designed parts, prototyping services, please feel free to contact us.

We have a very passionate team of seasoned designers, engineers, and technicians. They are ready to provide you high-precision and durable CNC machining services with excellent efficiency and processing accuracy.